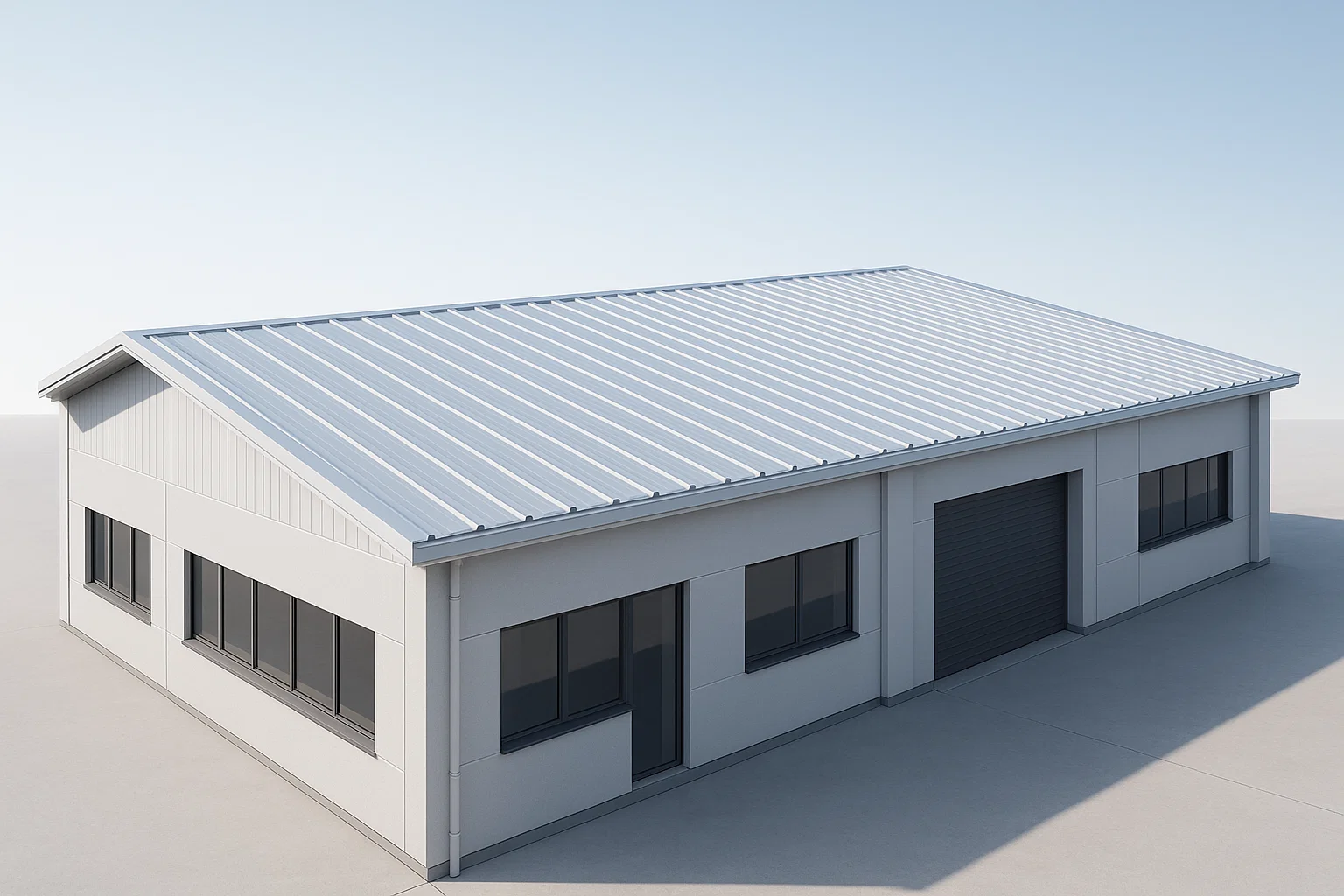

Steel Construction

Steel is the most accurate construction material for all ground classes and earthquake zones with its lightness compared to alternative products, high strength and durability, more elastic structure and ductility properties.

The manufacturing and assembly periods of steel structural elements are much shorter than other alternative structures. This ensures that construction, project and costing expenses are minimized.

Steel construction structures provide great economic gain and time advantage compared to alternative structures in foundation constructions and preliminary preparation works of areas requiring reinforcement.

Steel construction structures have the chance to pass wide spans without columns and sometimes without carriers in industrial structures. This both reduces the cost and allows the structure to be used in a more aesthetic way.

The manufacturing and assembly of steel structural elements are not affected by weather conditions. Depending on the workforce to be used, it provides the opportunity for uninterrupted work and assembly at every point where human power can be used appropriately.

Unlimited solution possibilities in architecture provide a much more aesthetic and future-oriented permanent trouble-free use in the project. It provides a fast and trouble-free transition in changes to be made from time to time and enlargement or reduction operations.

If desired, the entire steel carrier system can be dismantled without any loss and transported to any point in the world very economically. Being dismountable also provides the opportunity for temporary storage work on leased lands.

If desired, all the elements forming the structure and the carrier system can be produced with bolts. This dismountable feature prevents material loss with minimum loss in operations such as dismantling, transporting, changing, enlarging or reducing the steel construction structure.

Since the application and follow-up of the steel construction structure is constantly carried out in the construction site, high markup errors are prevented, and reliability and durability are kept at the highest level with tests in the computer environment.

Advantages

Fast assembly and construction time

High durability and long life

Earthquake resistance

Flexible design possibility

Technical Specifications

Fire Resistance:

Resistance decreases at high temperature

Prefabrication Suitability:

Precision production can be done with CNC Machines

Long-lasting and Durable:

Lasts very long with anti-corrosion coating

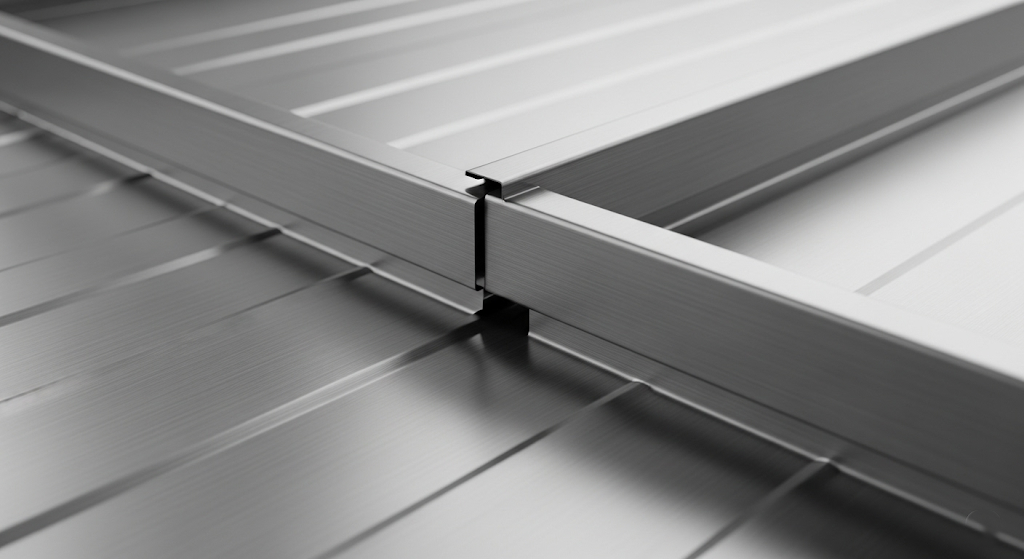

Low Thickness High Strength:

Provides high strength with thin sections

Premium Product

Premium Product